Control Solutions for Reliable and Clean Power Generation

For more than 150 years, power generation asset owners and OEMs have relied on us to meet their commitments to customers and the environment. Generating electricity has never been more challenging with increasing demand, decarbonization initiatives, alternative fuels, and renewable energy sources with variable output.

Our customers design, own and operate utilities, microgrids, data centers, commercial and institutional facilities, and power plants. Whether generating electricity for distribution to the grid or their own power demands, we help keep the lights on.

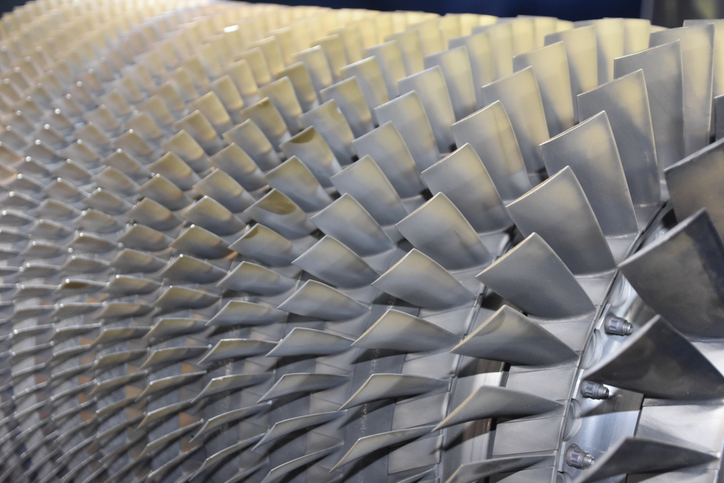

We support the power generation industry with our complete turbomachinery and engine control solutions. Our offerings include OEM-qualified, high availability/reliability control systems, valves, actuators and power management solutions.

Want more information?

Contact Us